When it comes to choosing materials for performance cycling components, carbon fiber and aluminum are two of the most debated. But is carbon fiber actually stronger than aluminum? The answer depends on what you mean by “stronger,” and how the material is being used.

Strength vs. Stiffness vs. Durability

Carbon fiber is often touted as being stronger than aluminum, but in reality, it’s more accurate to say that carbon fiber has a higher strength-to-weight ratio. This means it can deliver greater strength at a significantly lower weight. For components like cranksets, handlebars, and frames, this makes carbon ideal when reducing mass is critical.

Aluminum, on the other hand, is typically more ductile and impact-resistant. While it may be heavier, it can absorb more energy before failing, making it a reliable choice for riders who prioritize toughness over ultimate weight savings.

How They Perform in Cycling Components

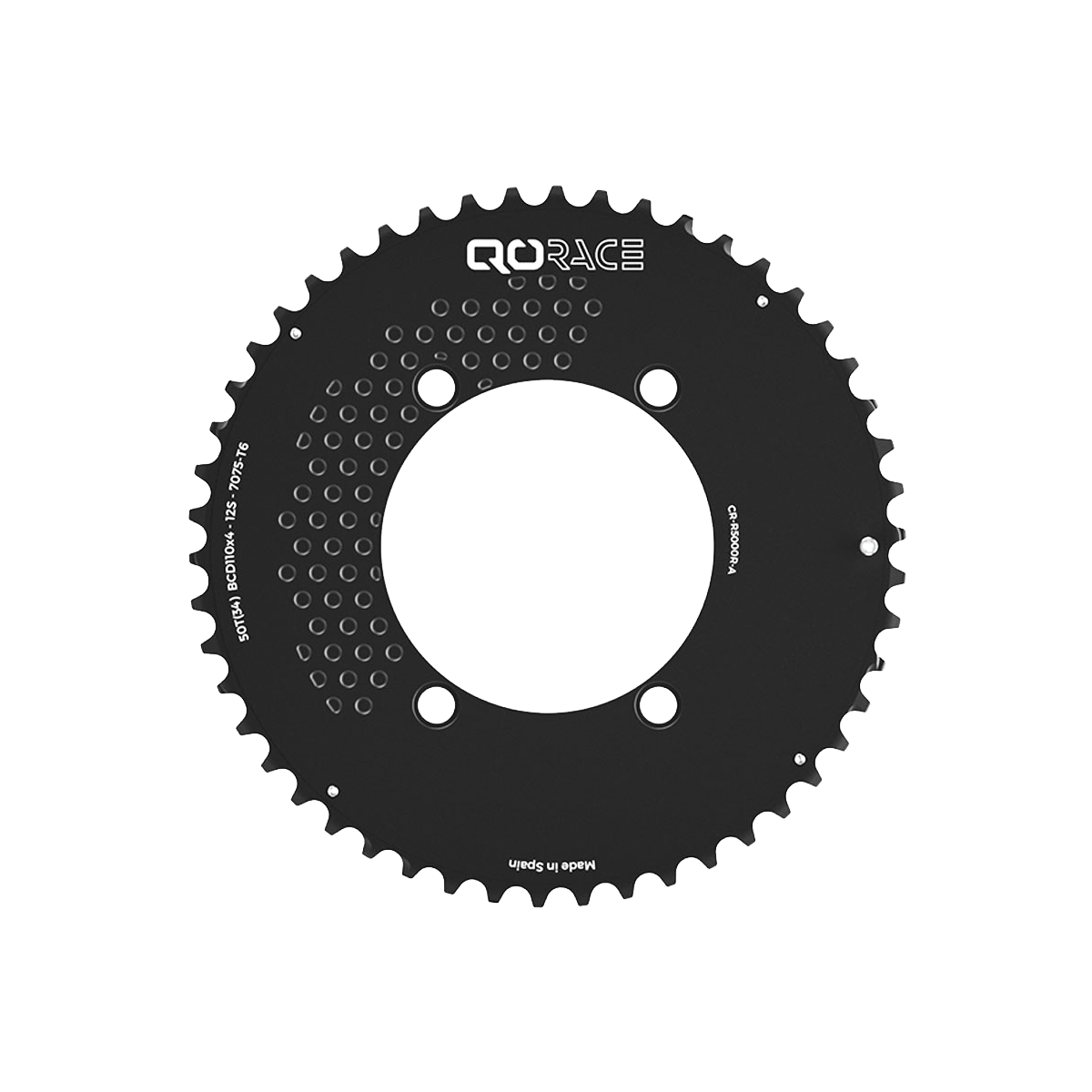

Carbon fiber shines in high-performance applications. Brands like QO, ROTOR, and SRAM use advanced carbon layups in cranksets to achieve exceptional stiffness and responsiveness while keeping weight to a minimum. Riders benefit from faster acceleration, improved vibration damping, and reduced fatigue over long rides.

Aluminum components are often found in mid-tier or budget setups, offering durability and ease of manufacturing. While they may not offer the same lightweight performance as carbon, they’re more resistant to crash damage and easier to repair or replace.

Which One Should You Choose?

If your priority is lightweight performance, especially in road racing or triathlon, carbon fiber is the superior choice. If you ride in rugged conditions or want something more forgiving and affordable, aluminum may be the better fit.

Ultimately, it’s not just about raw material strength. It’s about how the material is engineered and applied. High-quality carbon fiber, when designed properly, is incredibly strong, stiff, and efficient — and yes, in many cycling applications, it outperforms aluminum.