Carbon fiber is redefining what’s possible in the world of high-performance components. Long gone are the days when carbon was reserved exclusively for bike frames or aircraft fuselages. Today, advanced carbon composites are making their mark in the smallest, most demanding parts of every system.

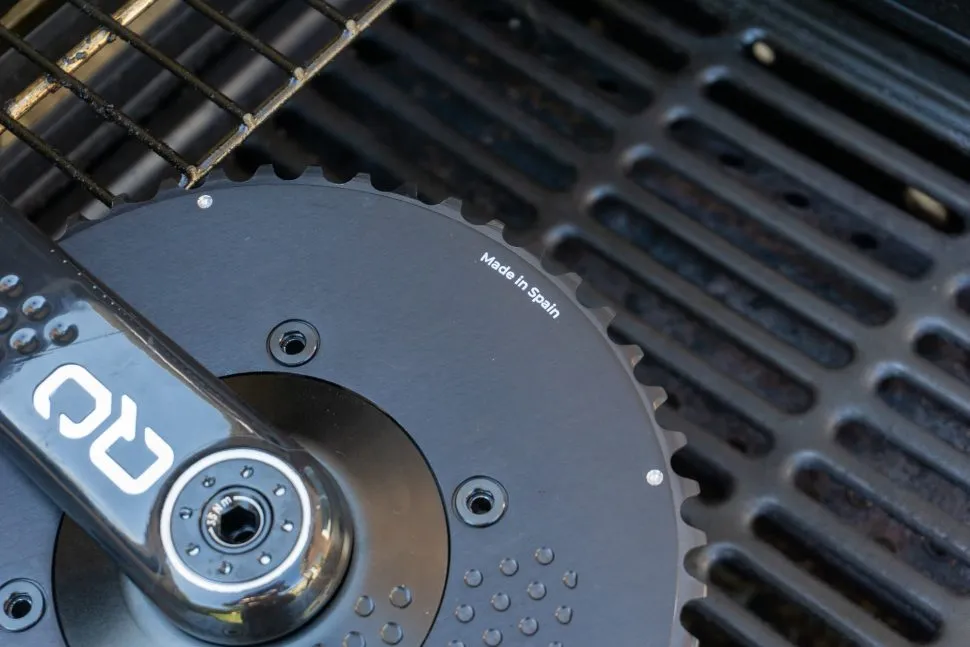

In cycling, carbon crank arms and handlebars deliver a combination of stiffness and vibration dampening that aluminum simply can’t match. Brands like QO, ENVE, and THM are setting new standards in weight reduction and responsiveness with carbon cranks, stems, and seatposts designed for competitive use. Thanks to layup optimization and hybrid structures like KevTex™, these components maintain structural integrity under extreme loads without compromising comfort.

The drone industry is also evolving rapidly with carbon fiber replacing aluminum and ABS in propeller arms, landing gear, and structural arms. Companies like DJI and Freefly use carbon to extend flight time, increase payload capacity, and reduce thermal expansion—all critical in high-altitude or long-range missions. Torsional rigidity and dimensional stability are crucial for accurate flight control, and carbon fiber offers both.

In aerospace and motorsports, the shift is even more dramatic. Formula 1 cars now use full carbon composite suspension arms and steering wheels, maximizing strength-to-weight ratio. Jet engine housings and wing components are increasingly produced with prepreg carbon fiber and resin infusion techniques, enabling precise aerodynamic shaping with lower fuel costs.

What’s driving this evolution? It’s not just the material itself, but how it’s being applied. Resin systems with enhanced thermal resistance, automation in layup procedures, and computer-optimized fiber orientation are enabling breakthroughs in both cost and performance.

CarbonRaw continues to spotlight this transformation by tracking new uses of fiber technology, highlighting cutting-edge brands, and analyzing the fabrication techniques behind elite components. As materials science advances, the possibilities expand—and we’re here to document every layer of it.

Carbon fiber is no longer limited to frames and shells. The future of performance gear lies in advanced carbon composites applied to every critical component. From handlebars and cranksets to drone arms and racing paddle blades, carbon delivers superior stiffness, reduced weight, and unmatched fatigue resistance. Discover how engineering innovation is redefining the limits of strength and precision across sports, mobility, and aerospace.